Featured Products

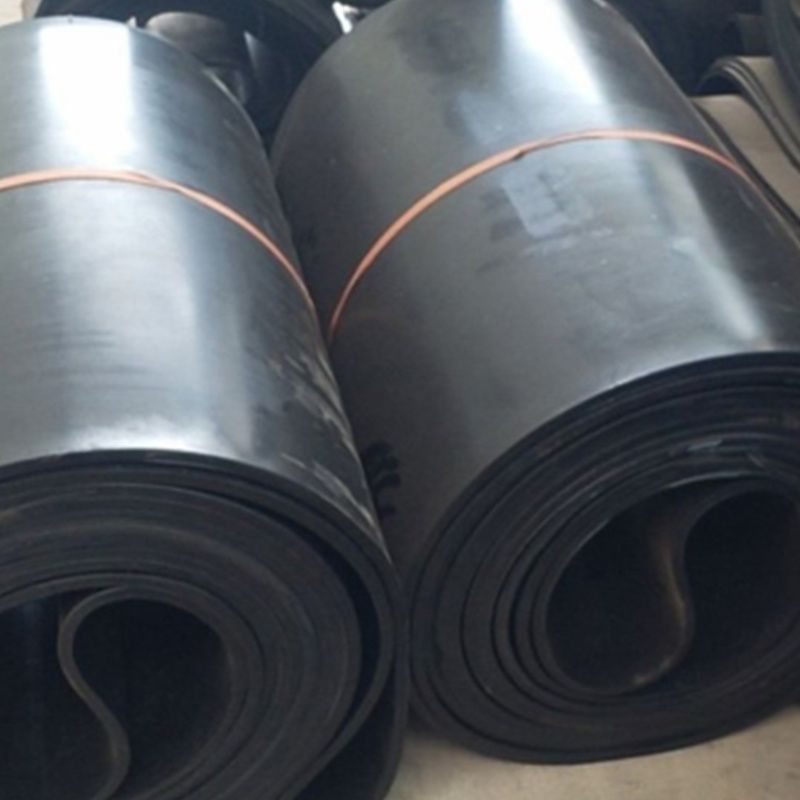

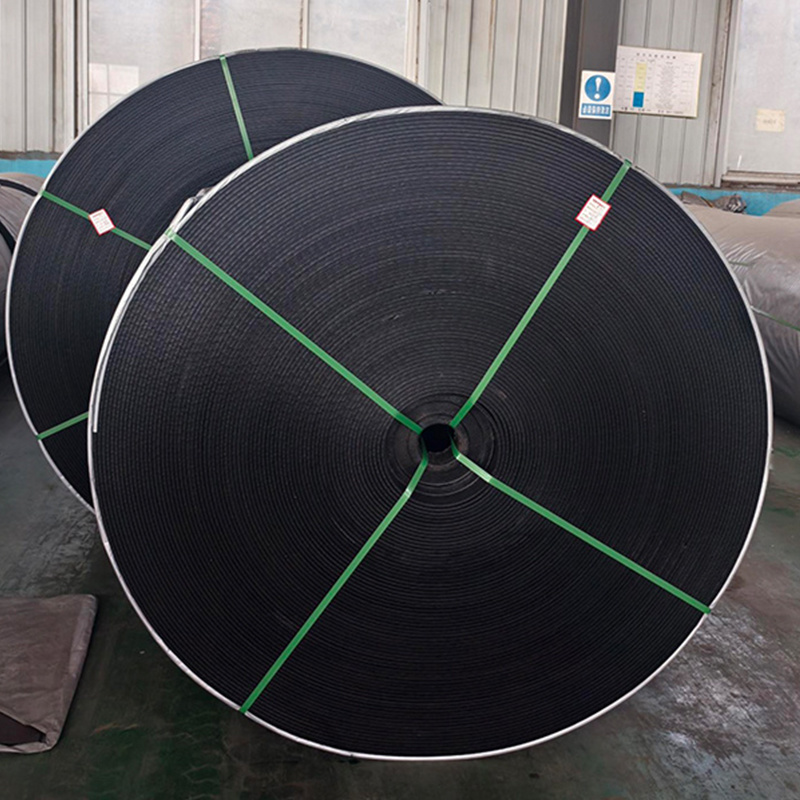

The company has introduced multiple conveyor belt production lines and excellent production equipment

Conveyor belt solutions customized to your needs

Strengthen international cooperation and exchanges, break through geographical limitations, and allow high-quality conveyor belt products and services to cover the global market

Based on our rich industry experience and cutting-edge technological knowledge, starting from the use, use environment and specification requirements of conveyor belts, comprehensively considering various factors, aiming to provide customers with better-performing conveyor belt solutions to ensure the stability and durability of conveyor belts in practical applications.

Established in 2009

Exported to more than 30 countries

Product Category

Registered Capital

Solutions

Our products are suitable for high load, wear resistance, long life, suitable for heavy machinery, mining, building materials and other harsh scenarios

Roller Coasters of News: A Thrilling Ride Through Current Events

Solutions

Rolling into Success: Unveiling Industry Case Studies

Solutions

Rolling with the Times: The Latest Trends in the Roller Industry

Solutions

Rolling Through Industry Solutions: The Ultimate Guide

Solutions

Rollin' Smooth: The Essential Role of Idler Rollers in Industry

Solutions

The Unsung Hero: Understanding the Idler Roller in Machinery

Solutions

Our Advantages

We can customize and develop and produce conveyor belt products according to the drawings or samples provided by customers, providing you with high-quality conveyor belt products and professional solutions.

R&D Strength

Driven by a passion for progress, our R&D team continuously explores advanced technologies and environmentally friendly solutions to meet the ever-changing challenges of the industry.

Quality Assurance

From raw material selection to final delivery, we adhere to strict international standards to ensure the durability and reliability of each conveyor belt.

Service Assurance

Continuously optimize product performance and service quality, with efficient, reliable and safe conveying solutions to help customers improve production efficiency, reduce operating costs, and create value for customers.

Customer Value Creation

Deeply explore the needs of customers in various industries, whether it is the mining, steel, port and other emerging fields in the heavy industry, we can provide customized conveyor belt solutions;

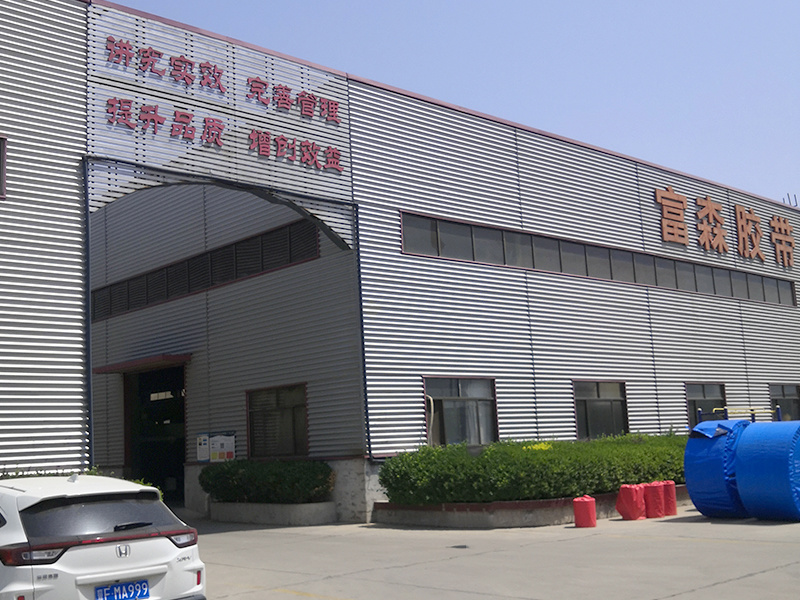

Workshop environment

Factory display

Factory environment (1)

Factory environment (3)

Factory environment (4)

Based in China, serving the world

Established in2009, Fusen in30+countries sales

Strengthen international cooperation and exchanges, break through geographical limitations, and allow high-quality conveyor belt products and services to cover the global market;

The sales network covers all provinces in China. In addition to domestic sales, products have been sold to more than 100 countries and regions around the world.

Blog

Fusen News

Performance characteristics of the integral core flame-retardant conveyor belt

Flame Retardant and Anti-Static: It has self-extinguishing properties against flame combustion and effectively prevents electrostatic accumulation, ensuring safe production. High Strength: Uses high-quality carcass materials to ensure stable operation of the conveyor belt under heavy load.

Specifications of nylon core conveyor belts

Core material: NN100, NN150, NN200, NN300, NN400, NN500, etc. Bandwidth: 100mm - 3000mm.

Application scenarios of integral core flame-retardant conveyor belts

Coal Mining Industry: Suitable for underground coal transportation, meeting the strict requirements of coal mine safety production. Metallurgical Industry: Used for material transportation in high-temperature and high-wear environments. Chemical Industry: Suitable for transporting corrosive chemical raw materials and products.

Characteristics of nylon core conveyor belts

High Strength: The belt is thin but has high tensile strength, much higher than ordinary conveyor belts. It can withstand large tensile forces and is suitable for long-distance, high-volume material conveying. For example, in large mine ore conveying systems, it can efficiently transport large quantities of ore from the mining site to the processing site.