Purpose

• Heat-resistant conveyor belts are mainly used for conveying high-temperature materials, such as sintered ore, hot coke, cement clinker, and hot castings. According to the main manifestations of heat-resistant belt damage and loss of conveying capacity, and different heat-resistant levels, ternary ethylene propylene or styrene-butadiene rubber is used as the cover rubber; high-strength, high-permeability polyester canvas or cotton canvas is used as the reinforcing layer. Heat-resistant glass cloth can be laid between the cover rubber and the carcass layer to improve the service life of the heat-resistant belt. According to customer requirements, it can be made into a circular belt.

• Heat-resistant and high-temperature conveyor belts are widely used in coal, mining, ports, metallurgy, power, and chemical industries for material conveying.

Features

1. High strength, thin belt body, light weight.

2. Using nylon/EP polyester/NN/EE rubber-coated canvas as the carcass material.

3. The belt body is soft, has good troughing properties, and good elasticity.

4. Excellent high-temperature and heat resistance, can withstand 250°C high temperature for a short time.

5. Suitable for large loads, faster speeds, and medium and long-distance material transportation.

6. Stable operation, no deviation.

Specifications and Technical Parameters of Heat-Resistant and High-Temperature Conveyor Belt Carcass Fabric Core

| Specifications and Technical Parameters of Heat-Resistant and High-Temperature Conveyor Belt Carcass Fabric Core | ||||||||||

| Fabric Type |

Fabric Structure | Fabric Model | Rubber Cloth Thickness | Strength Series (N/mm) | Cover Rubber Thickness (mm) |

Width Range (mm) |

||||

| Warp | Weft | 2 layers | 3 layers | 4 layers | Top Cover Rubber | Bottom Cover Rubber | ||||

|

Nylon EP Polyester NN EE

|

Polyester | Nylon | Nylon/EP Polyester/NN/EE-80 | 1.00 | 160 | 240 | 320 | 0-12 | 0-10 | 300-2500 |

| Nylon/EP Polyester/NN/EE-100 | 1.00 | 200 | 300 | 400 | ||||||

| Nylon/EP Polyester/NN/EE-125 | 1.05 | 250 | 375 | 500 | ||||||

| Nylon/EP Polyester/NN/EE-150 | 1.10 | 300 | 450 | 600 | ||||||

| Nylon/EP Polyester/NN/EE-170 | 1.10 | 340 | 510 | 680 | ||||||

| Nylon/EP Polyester/NN/EE-200 | 1.20 | 400 | 600 | 800 | ||||||

| Nylon/EP Polyester/NN/EE-250 | 1.40 | 500 | 750 | 1000 | ||||||

| Nylon/EP Polyester/NN/EE-300 | 1.60 | 600 | 900 | 1200 | ||||||

| Nylon/EP Polyester/NN/EE-350 | 1.70 | 1050 | 1400 | |||||||

| Nylon/EP Polyester/NN/EE-400 | 1.90 | 1600 | ||||||||

| Nylon/EP Polyester/NN/EE-500 | 2.10 | 2000 | ||||||||

Bonding strength and elongation performance meet the following table

| Bonding Strength, Elongation Performance | |||||

| Belt Core Material |

Bonding Strength | Elongation Performance | |||

| Interlayer N≥mm | Between cover and fabric layer N/mm |

Full thickness longitudinal breaking elongation | Full thickness longitudinal reference force elongation | ||

| Cover layer thickness ≤1.5mm | Cover layer thickness ≥1.5mm | ||||

|

Nylon EP Polyester NN EE |

≥5 | ≥4.5 | ≥5 | ≥10% | ≤4% |

The cover performance of heat-resistant and high-temperature conveyor belts meets the following table

| China GB/T7984-2013 GB/T 32457-2015 Conveyor Belt Cover Layer Performance | |||||

| Cover Layer Grade | Tensile Strength | Elongation at Break | Abrasion Loss | Change rate of tensile strength and elongation at break after aging | |

| Mpa | Kgf/cm2 | % | mm 3 | % | |

| H | 24 | 240 | 450 | 120 | -25 ~+25 |

| D | 18 | 180 | 400 | 100 | -25 ~+25 |

| L | 15 | 150 | 350 | 200 | -25 ~+25 |

The physical and mechanical properties of the heat-resistant belt cover layer after the heat resistance test meet the following table

| Item | Model | ||||

| T1≤100°C | T2≤125°C | T3≤150°C | T4≤180°C | ||

| Range of variation | |||||

| Hardness | Difference between after and before aging | +20 | +20 | ±20 | ±20 |

| Maximum value after aging | 85 | ||||

| Tensile Strength | Minimum value after aging | 12 | 10 | 5 | 5 |

| Performance change rate/% | -25 | -30 | -40 | -40 | |

| Elongation at Break | Performance change rate/% | -50 | -50 | -55 | -55 |

| Minimum value after aging | 200 | 200 | 180 | 180 | |

Covering rubber quality/grade standard performance parameters

| German standard DIN-22102 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Wear amount ≥mm 3 | Interlaminar shear strength (N/mm) | Bond strength between covering layer and fabric layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Covering layer thickness >1.5mm | |||||

| W | 18 | 400 | 90 | ≥5 | 3.5 | 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| British Standard BS 490 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Wear amount ≥mm 3 | Interlaminar shear strength (N/mm) | Bond strength between covering layer and fabric layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Covering layer thickness >1.5mm | |||||

| M | 24 | 450 | - | ≥5.25 | 3.15 | 4.5 |

| N | 17 | 400 | - | |||

| Australian Standard AS 1332-2000 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Wear amount ≥mm 3 | Interlaminar shear strength (N/mm) | Bond strength between covering layer and fabric layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Covering layer thickness >1.5mm | |||||

| A | 17 | 400 | 70 | 6 | 4 | 4.8 |

| E | 14 | 300 | - | |||

| F | 14 | 300 | - | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| South African SANS 1173:2005 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Wear amount ≥mm 3 | Interlaminar shear strength (N/mm) | ||

| Bond strength between covering layer and fabric layer (N/mm) | ||||||

| A | 18 | 400 | 90 | ≥7 | ≥5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

Specifications and Technical Parameters of Heat-Resistant and High-Temperature Conveyor Belt Carcass Fabric Core

| Fabric type | Fabric Structure | Fabric Model | Tape thickness (mm/p) | Strength Series (N/mm) | Cover Rubber Thickness | Width range (mm) | ||||||

| Warp | Weft | 2 layers | 3 layers | 4 layers | 5 layers | 6 layers | Upper covering layer | Lower covering layer | ||||

|

Nylon EP Polyester NN EE |

Nylon | Nylon | Nylon/EP Polyester/NN/EE-100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 0-12 | 0-10 | 300-2500 |

| Nylon/EP Polyester/NN/EE-125 | 1.05 | 250 | 375 | 500 | 625 | 750 | ||||||

| Nylon/EP Polyester/NN/EE-150 | 1.10 | 300 | 450 | 600 | 750 | 900 | ||||||

| Nylon/EP Polyester/NN/EE-200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| Nylon/EP Polyester/NN/EE-250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| Nylon/EP Polyester/NN/EE-300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have a pre-shipment inspection procedure?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

High-temperature conveyor belt

Contact Us

Category

Related Products

White embossed herringbone pattern food-grade conveyor belt

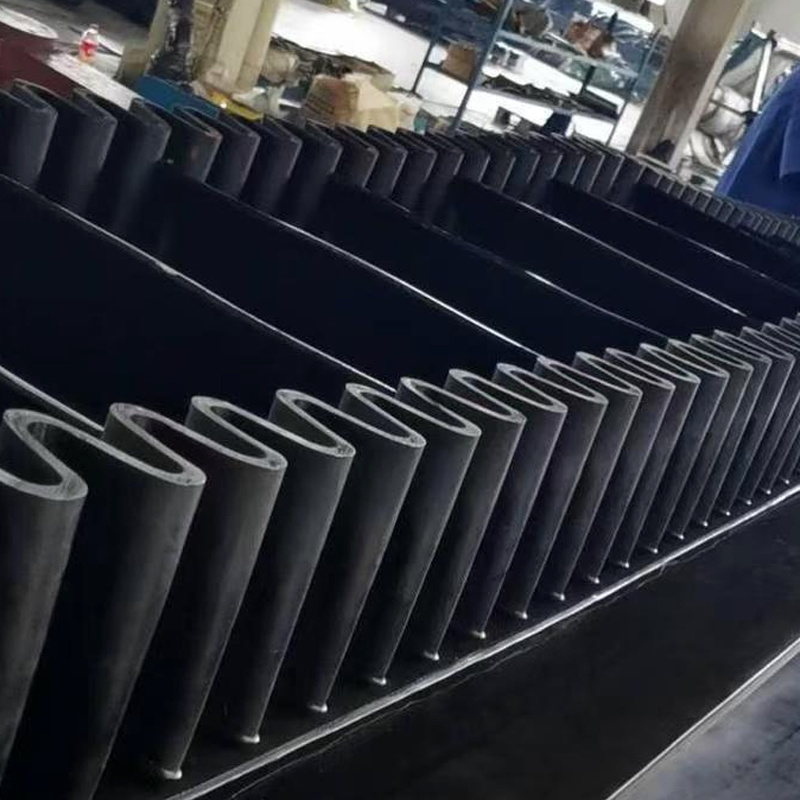

Steeply inclined conveyor belt

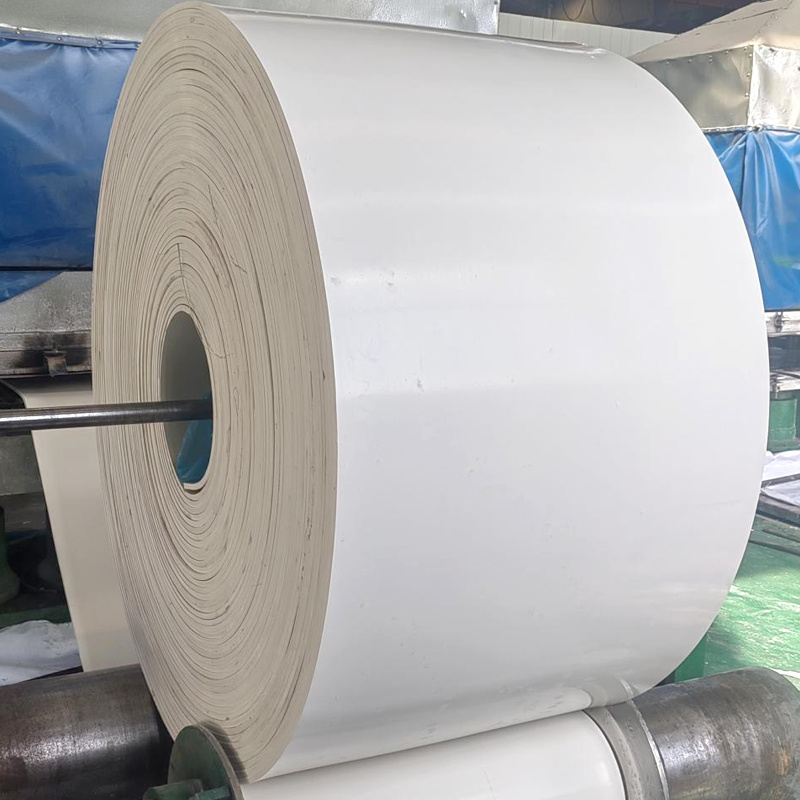

White food-grade conveyor belt